ZARAH JUAN, ESTUDIO JUAN

“I was a flight attendant for several years and used to be based out of Japan. I asked my colleagues ‘How come there are bags being sold in supermarkets here?’ They told me that those were simply reusable bags to carry grocery and that’s when it downed on me that it was just we Filipinos still using plastic bags. I fell in love with the idea and when I flew back to Manila, I tried to make my own bag. I went to a silk screen maker with my design and asked them to make something for me based on that. This is how I made my first 2 bags. I carried them around here and when I traveled and whenever people asked, I would explain that those were reusable bags for groceries and that they should consider that too. When friends asked for a bag, I would give them one of mine and make some more. Then someone approached me and said, ‘your bags are very practical and make sense. Can you please make 10 for me as giveaways at my son’s baptism?’ I said ‘sure’. At that time I had no machines of my own. I would go to a place where you rent sawing machines for 15 pesos and together with a dressmaker we would make a bag in one hour. I would buy the fabric at the market, cut it and she would stitch it together. So technically you can say that I started my business with 15 pesos.”

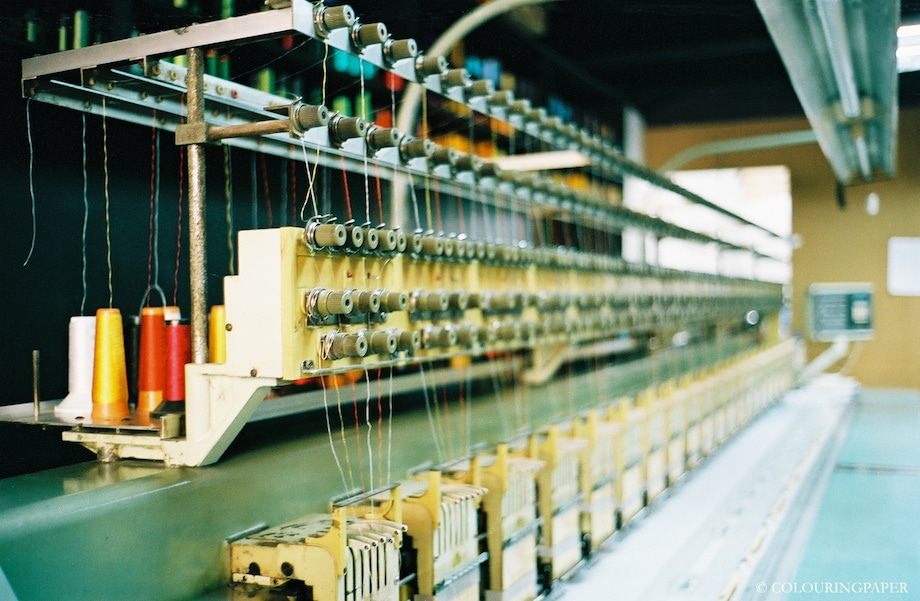

“After that, I kept getting small orders from friends. Then one asked me for 100 pieces to be used as thank you gifts at a wedding and I decided to invest in 2 machines. This was in 2006 and at that time I was still working as a flight attendant and would make home when back in Manila. Once I posted a picture of my bag on a local free online platform and after several months I got a call from the largest mall in the Philippines. They asked me if I was a greenbag maker and I said yes. I was invited to their offices and they said they wanted to order 4000 bags for a launch event 3 weeks later. All other bag makers they contacted said they didn’t know how to make green bags because they thought there was a special technique for it. I told the mall staff I had only 2 machines so I could not make that many bags. The big boss said, ‘That’s your challenge. Are you going to turn down this order or are you going to take it?’ I told them I would take it but after I left their offices, I started panicking. I bought 2 more sewing machines and had part of the bags made by unemployed ex-factory workers in Bulacan, the province I came from. Still, after one week I called the mall and told them that I wanted to be honest and that I could only deliver half of the order by their deadline but if they gave me more time, I would complete the order. They accepted my proposal and have been ordering my bags every since.”

“Once I got repeat orders from the mall, I realized I could make a decent living from it so I quit my job. The mall recommended me to one of their sister companies – Kultura – which sells high-quality local products and souvenirs to tourists and Filipinos living abroad. They liked my prints and asked me to make t-shirts for them. I told them I made bags, not t-shirts. ‘Those bags don’t sell here’, they said. I decided to make both t-shirts and bags anyway and that’s what I delivered to them. ‘You are so stubborn, we told you we only wanted t-shirts.’ Since the bags looked good, they ordered some and to their surprise, they sold them all in one week. They ordered more and also asked me to make more products with the same designs so I created a full collection of bags, mugs, key chains, pillows, teddy bears, and more with that specific target audience in mind.”

“When my orders got bigger, I started getting into cashflow issues because my clients would only pay 45 days after delivery. Initially I tried to get a loan from a bank but it didn’t work out because I didn’t have enough assets for collateral. In my typical stubborn fashion, I was not going to give up that easily. I went to one of my largest client and asked to be paid on delivery from then on. They said it was not possible. I told them that in that case I wouldn’t be able to fulfill their large orders as quickly as before because I was short of cash to buy the raw materials. In the end, they said ‘ok, we’ll hook you up with our bank and put a good word for you’. So that’s how I got my credit line. Thinking about that now I almost can’t believe how gutsy I had been but I am glad I did. My stubbornness paid off once again.”

“A lot of my large clients need to come up with new collections every month but have little time and staff to do research so I do the legwork for them. They give me a theme and I do the research and take care of pricing, trends, and execution so that all they have to do is pick what designs they like and order. I like doing this because I am learning all the time and I continue to grow. It’s also what differentiates me from my competitors.”

“When people asked me how I learned to make bags, I always tell them that it’s because of my childhood. I grew up in a very simple setting, in a very small house near the river. To pay for school fees my mom set up a sari-sari store and sometimes she would ask me to tend the store. I would get really bored because the only toy we had was a doll that I shared with my 3 sisters. It was a hand-over from a cousin and came with only one skirt and one shirt. So when I got bored, I would go to the dressmakers in the neighborhood, collect all the cut fabric, and then stich it into clothes for the doll while I waited for customers at the store. I think it’s because of this experience that I understand the logic of making a bag, how to cut it and how to stitch it together.”

“When I started making bags I would go to buy accessories and lace from a store here in Makati owned by an older woman. The first time she asked me so many questions – why I was buying that and what I was trying to do – so I told her my story. She said, ‘Ok, I will help you’. And she spent hours teaching me how to do things, where to buy supplies, what to pay attention for, etc. I asked her, ‘mam why are you doing this? Aren’t you worried that one day I might be your competition?’ She said, ‘I don’t mind it. I help you because if we don’t teach others, one day the industry will die’. So now I am doing the same. I teach bag design at SoFA – School of Fashion and the Arts –and once a month I host a mentoring group with other designers in this studio, where we invite students to come and listen. It’s basically just ranting and venting and sharing experiences on how we dealt with issues, how we solved problems. Students sit here and listen and learn about real life issues straight from the designers themselves. It’s very inspiring for all of us. Now I know it’s not just me that is experiencing all these things, it’s everybody.”

“I’m starting to make my own collection but it’s very new, I am still testing the market. I made 10 leather bags like this one and posted a picture on my personal instagram account two weeks ago. In less than 30 min my bags sold out. I made more, posted again and got an order of 20 pieces and then another 20 pieces. I offer monogramming of 3 letters or characters. I’m actually the one doing it right now. I want to practice so that I can teach my employees. I always believe in this principle. If I cannot do it, then I cannot teach others.”

Company: Estudio Juan & Greenleaf Eco Bags

Location: Manila

Founded: 2006

No of Employees: 132

Woman-owned & led